EQUIPMENT PROCUREMENT SERVICES (EPS)

KLINGER EPSfull or KLINGER EPSsmart

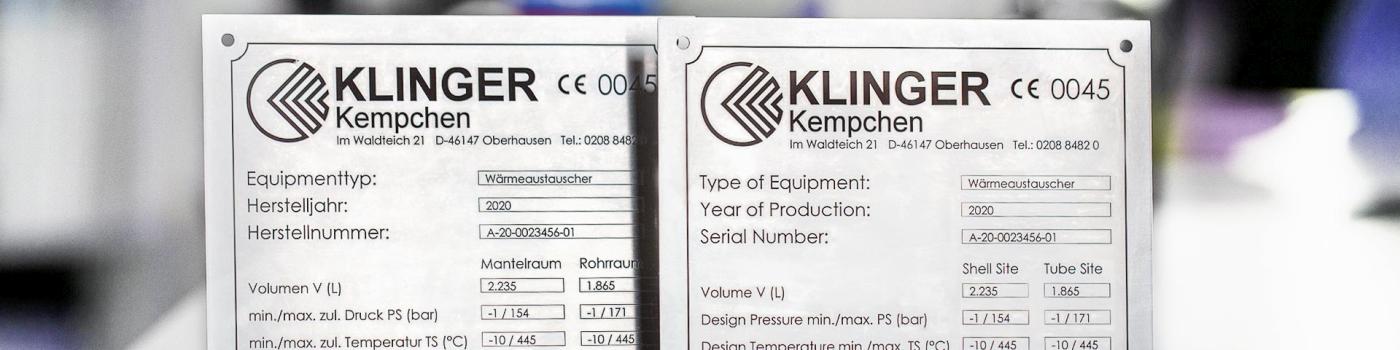

KLINGER Kempchen GmbH with its KLINGER Engineering Team is already known to you as a competent and flexible partner in the field of problem solving in case of leakages. Technical engineering knowledge and team experience are our basis for efficient problem solutions.

We would like to recommend our expertise to you even without previous leakage. While we love the challenge of finding solutions for leakages, wouldn’t it make more sense to prevent leakages in advance? Many new equipments do not pass the pressure test during production approval. Sealed joints often become leaky before the required test pressure is reached. Other equipments and/or sealing connections leak at the first commissioning and often remain so.

The reason for most leakage phenomena is the selected design codes. Many well-known regulations such as AD 2000, DIN EN 13445 or ASME Section VIII Div. 1 focus on strength design. The components designed in accordance with these regulations are sufficiently dimensioned for the planned pressure and temperature conditions, but do not take into account the safeguarding of the equipment with regard to reliable functioning.

It is not only regulations for the design of equipmets that show weaknesses when it comes to tightness and function: Many designers also over- or underestimate the selected gaskets and/or sealing systems. Particularly in the case of critical application limits, there is often a lack of important experience and the correct method of calculating with regard to the sealing function.

Instead of time-consuming and cost-intensive solution searches we rather convince you with the better solution for the fields of devices and containers: our KLINGER EPSfull or KLINGER EPSsmart service.

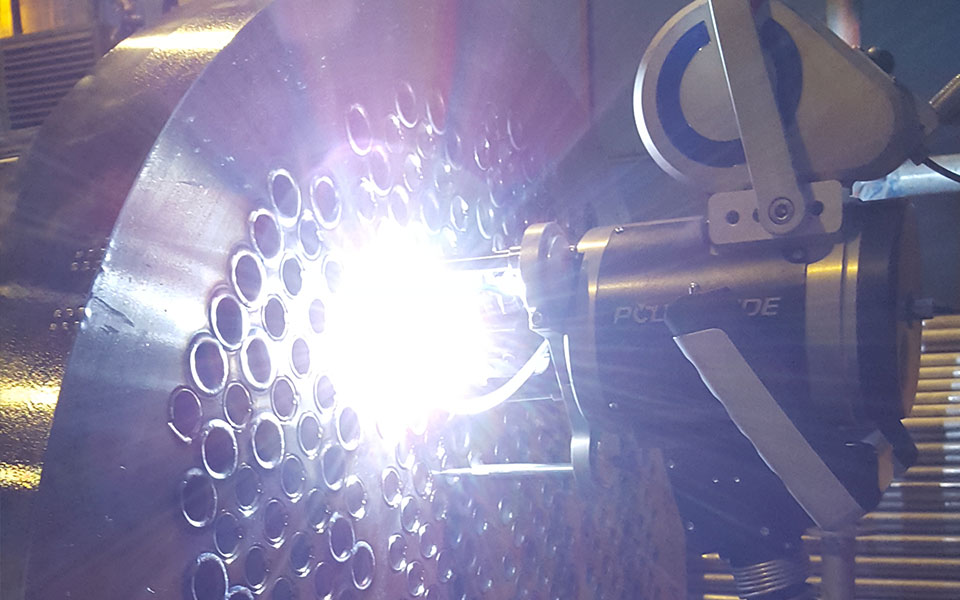

Take advantage of our complete and in-depth expertise in the construction and manufacture of pressured equipments! We are not only familiar with the technical and constructional problems that occur especially in borderline areas, but also with their technical solutions. Therefore we divide our service into two competences: KLINGER EPSfull and KLINGER EPSsmart.

KLINGER EPSfull or KLINGER EPSsmart – Comparison

KLINGER EPSfull:

You need a new equipments or storage tank? No problem! We will gladly deliver it to the installation site.

KLINGER EPSsmart:

We place our complete and in-depth specialist knowledge at your disposal for the request, construction and manufacture of equipments and storage tanks.

Preparation of request specifications taking into account your requirements as well as optimisation by our engineering team – request of equipment at approved and specially selected manufacturing companies – offer evaluation and price comparison – complete support and responsible management of all processes up to acceptance and delivery of the final product.

One contact person: the Engineering Team of KLINGER Kempchen GmbH. Your advantage: Bundling of all responsibilities in one hand and use of the most technically mature solution.

You decide which alternative is the best solution for you. Whichever service you choose: At any time you have complete transparency in drawings and documents, prices and delivery times.

We place the highest demands on our service and offer the greatest flexibility in combination with maximum transparency, clear results without surprises, as well as compliance with all requirements and schedule plannings.

The extension of our service to the field of equipments and storage tanks. makes us an efficient partner of the industry.

Performance comparison

| Pre-dimensioning | KLINGER EPSfull | KLINGER EPSsmart |

|---|---|---|

| Selection of building regulations (Design Code) | ||

| Pre-selection of main materials and alternatives | ||

| Creation of inquiry specification based on customer requirement | ||

| Pre-dimensioning and sketching (shell, nozzles, flanges, tube sheet, stability etc.) | ||

| Corrosion analysis and service life evaluation | ||

| Consideration of special load cases |

| Commercial processing | KLINGER EPSfull | KLINGER EPSsmart |

|---|---|---|

| Selection of potential manufacturers / producers in consultation with customers | ||

| Inquiry of the equipment at selected Producers / Manufacturers | ||

| Inquiry support in case of queries from manufacturers / producersr | ||

| Offer evaluation / offer comparison Transparent offer discussion with customers | ||

| Award / contract negotiation | ||

| Ordering / commissioning of the equipment (Manufacturer in the sense of the PED 2014/68/EU) |

| Technical processing | KLINGER EPSfull | KLINGER EPSsmart |

|---|---|---|

| Design support by KLINGER Engineering (queries, change management, deadline tracking) | ||

| Design Review KLINGER Engineering (especially for gasket resp. flange connections; review of selected main components)) | ||

| Design Review KLINGER Engineering (all gasket resp. flange connections; review of all main components) | ||

| Preparation of design documents for preliminary review (NoBo/ASME Inspection Agency) | ||

| Coordination / monitoring of the preliminary examination (NoBo/ASME Inspection Agency) | ||

| Approval of production documents together with customers | ||

| Introduction Material procurement, testing and production | ||

| Progress reports and deadline tracking | ||

| Production reports and quality assurance | ||

| Acceptance coordination | ||

| Delivery and unloading | ||

| Installation, mounting and assembly | Auf Anfrage |