PACKINGS

All common variants in our finished goods warehouse

In contrast to static seals, stuffing box packings are mainly used in dynamic installation situations. Where the escape of liquid or gaseous media at the housing passage of moving elements such as spindles or shafts is to be avoided. Both rotating and oscillating movements must be compensated for. Factors such as material, impregnation and the manufacturing process of the packing are decisive for reliable sealing.

KLINGER Kempchen offers you all common materials for this purpose, such as graphite, PTFE, aramid, etc., which are produced in-house in all required manufacturing processes. This applies to braided packings as yard goods as well as to pre-pressed and preassembled packing systems such as the packing set K80S TA-HT. In order to be able to cover your short-term requirements, we keep all common variants in stock in our finished goods warehouse. In addition, our technical consulting service will determine the individual solution for your installation situation.

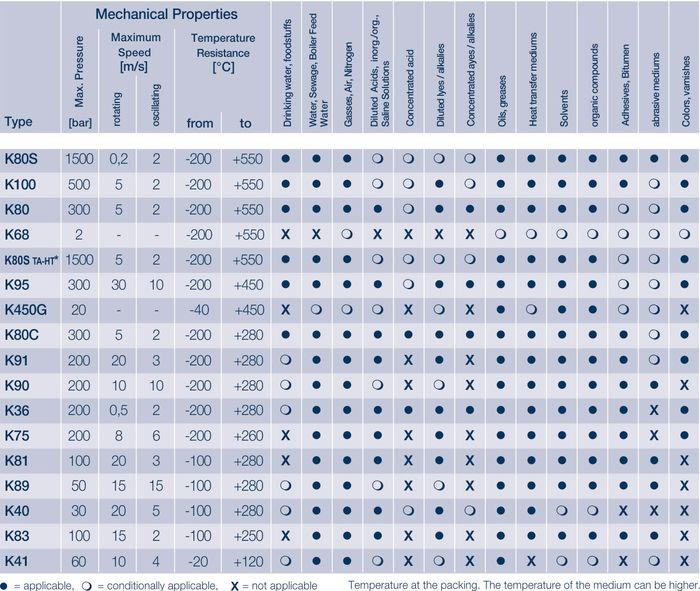

PACKING TYPES

Size of the Gap between Spindle, Gland Packing and Housing

If we designate the outer diameter of the spindle as d1 and the interior diameter of the gland or of the bottom ring as d2, then t = (d2 – d1)/2 is valid for the median radial gap between the spindle and the spacer or the bottom ring. In the case of an off-center position of the spindle or rod, the gap can double to one side to

2t = d2 – d1.

The table shows reference values for the maximum permitted size of the gap t in reference to the packing material. The influence of the operating pressure to be sealed was taken into account in this respect, as generally the smaller packing widths are inserted for the higher pressures.

Tolerances and the Composition of the Surface Area

For the rod or spindle, the accuraey degree should be h9. The surface area roughness should be Rz ≤ 2,5 µm or alternatively Ra ≤ 0,6 µm.

For the rod or spindle, the accuraey degree should be h9. The surface area roughness should be R ≤ 2,5 µm or alternatively R ≤ 0,6 µm.

For the gland, the tolerance accuraey degree D10 was proven. The surface area

roughness should be R ≤ 6,3 µm or alternatively R ≤ 2,5 µm.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

![]() Product documentation PACKING TYPES (pdf)

Product documentation PACKING TYPES (pdf)

![]() Installation instructions for packing rings (pdf)

Installation instructions for packing rings (pdf)

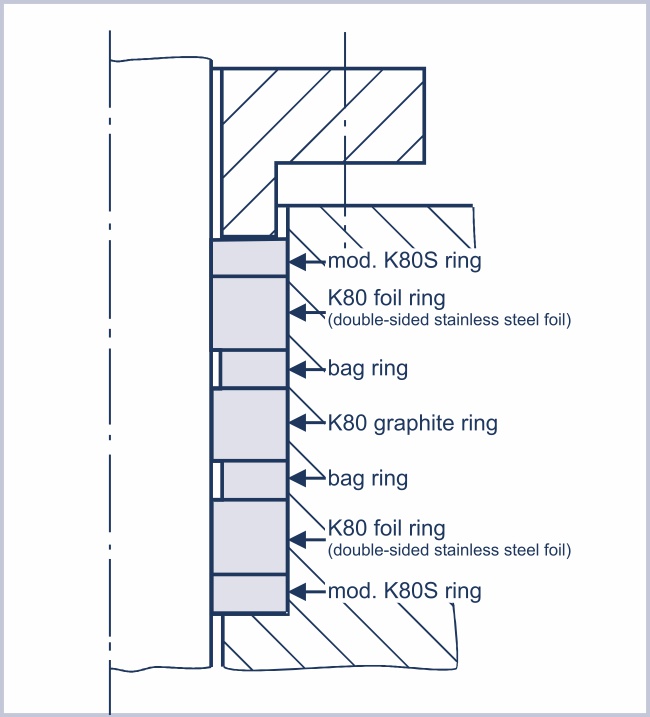

PACKING UNIT K80S TA-HT

BLOW-OUT PROOF TA-LUF

TA-Luft demands the ”use of high-quality gaskets“. This high level of quality for flanges and fittings is defined in the VDI 2440 ”Emissions Reduction in Petrol Refineries“ Directive. Alongside high-quality seals for control and shut-off devices such as metal bellows with a down-stream safety stuffing box, sealing systems such as the TA-Luft K80S TA-HT Packing can be used.

The first criterion for the equivalence is that the design layout of the sealing system permanently produces the intended function under operating conditions.

Secondly, the specific leakage rates must meet the following limits:

» 10-4 mbar-l/(s-m) at sealing system temperatures below 250 °C or 10-2 mbar-l/(s·m) at sealing system temperatures greater than or equal to 250 °C.

The requirements placed upon these sealing systems are as varied as the applications, meaning that selection is performed according to prescribed criteria. In doing so, the application parameters such as temperature, pressure, medium, type of movement and maximum applicable lifting force as well as the number of expected lifts during the entire period of operation must be taken into account.

K80S TA-HT is a packing unit with a total of seven rings. They partly consist of rings manufactured from graphite with stainless steel sheet inserts and partly consist of rings manufactured using flexible graphite as well as stainless steel foils located in between. The K80S TA-HT was classified as high-quality packing within the meaning of the TA-Luft for temperature ranges greater than or equal to 250 °C by the MPA in Stuttgart with certificate no. 0005/2012.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

![]() Product documentation PACKING UNIT K80S TA-HT (pdf)

Product documentation PACKING UNIT K80S TA-HT (pdf)

PACKING INSTALLATION KIT

Packing Installation Kit

The Kempchen Packing Installation Kit is suitable for removing old packings from stuffing boxes of, valves, pumps, agitators, etc. It is delivered in an impact resistant case with a foam rubber insert. The case is equipped with the most commonly used packing extractors, the corresponding replacement tips as well as a packing cutter. Each tool has its own place in the case due to the separate spaces in the foam insert.

With the Kempchen Packing Installation Kit in the case, the assembler has a universal and indispensable help aid at hand.

Packing Cutting Equipment

The Kempchen Packing Cutting Equipment allows for the cut-out of entire packing rings made from bulk stock. Many advantages arise from its simple handling, such as cutting without waste and scrap, high reliability and time savings. The Kempchen Packing Cutting Equipment is designed for ring averages up to 150 mm and a packing width up to 25 mm.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.