3D DESIGN AND FINITE ELEMENT ANALYSIS

Verification of damage theories

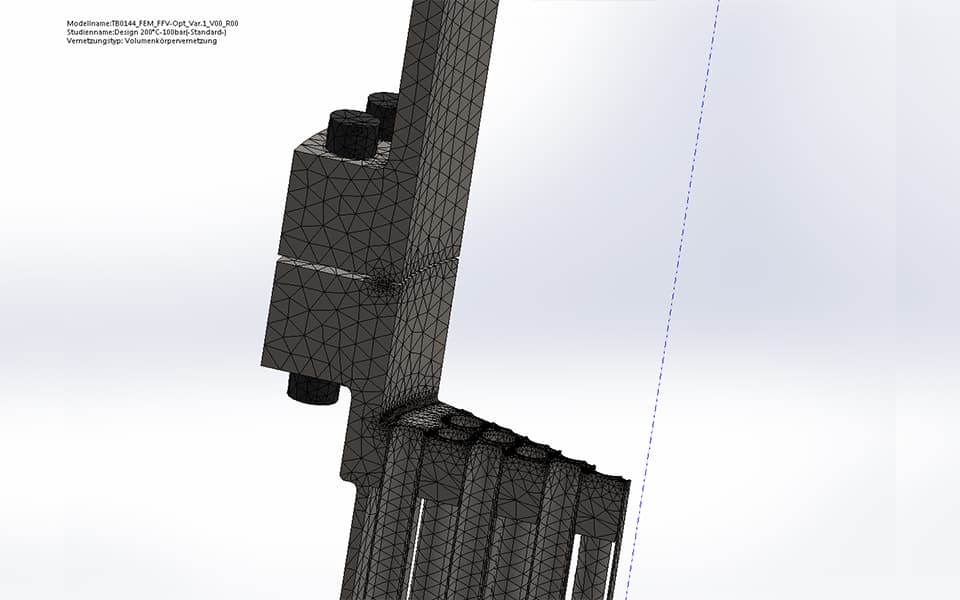

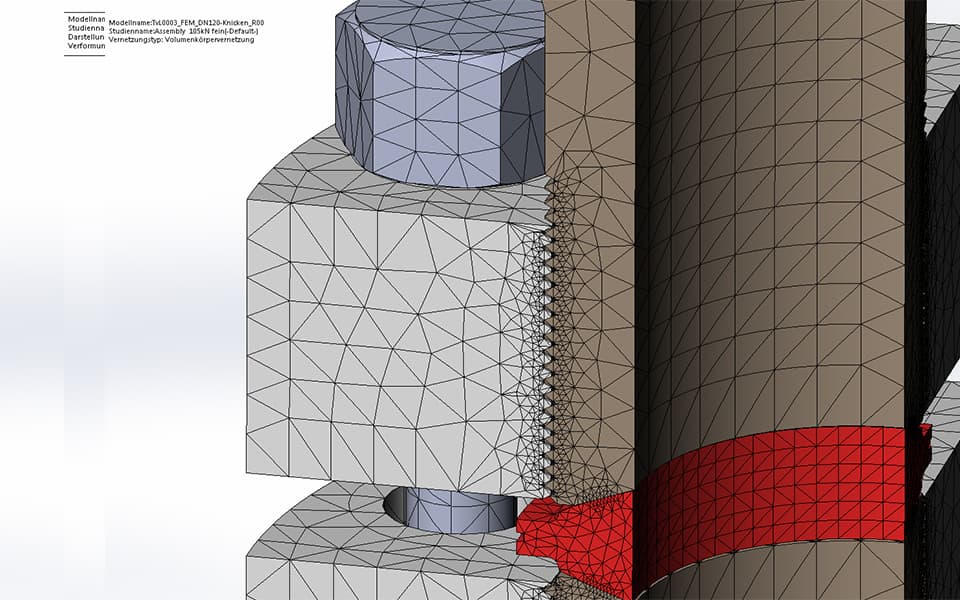

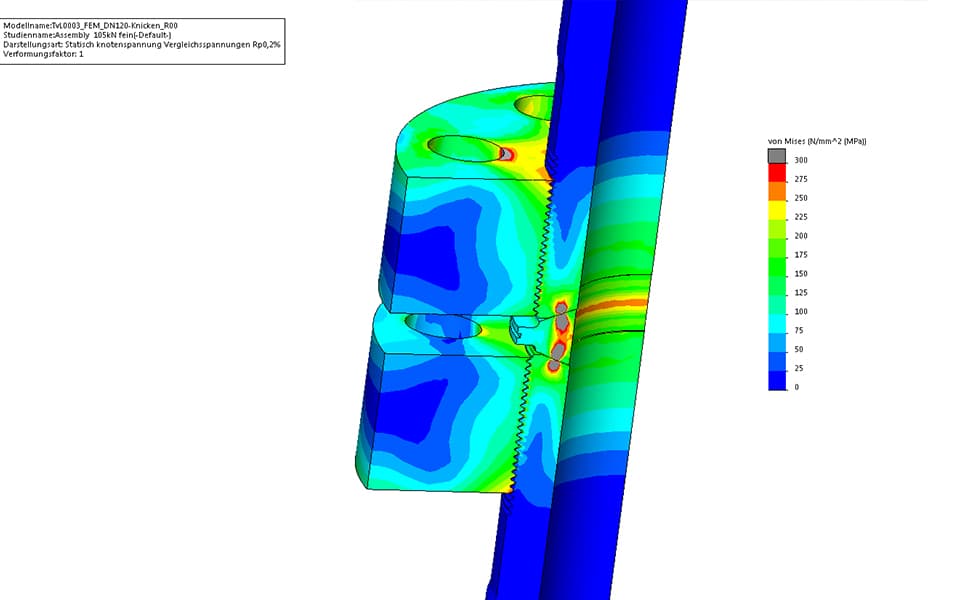

If you have run out of analytical calculation method options or if the component geometry or operating modes are very complex, we are also capable of helping you further. Thanks to our expertise, we can offer you three-dimensional modelling with subsequent linear or non-linear finite element simulation.

We pay special attention to:

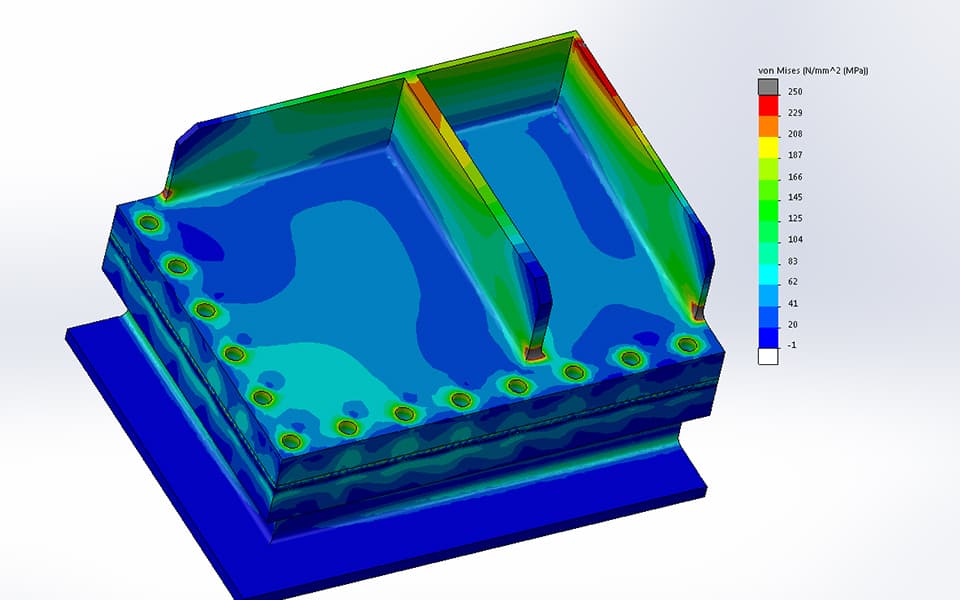

- Determining the load limit before damage to components occurs

- Calculating deformation, tension and expansion

- Presenting the contact situation between the components and gaskets

- The effect of temperature on component load

- Determining critical differential movements caused by asymmetrical thermal stress

- Tension analyses and tension categorisations

3D design with subsequent FEM simulation

FEM analysis is a tool which is frequently used to verify damage theories, particularly as part of damage investigations.

In this context, we can offer you:

- for gaskets at the main power connection / metal to metal contact type

- for flange and sealed connections of all kinds

- for metal gaskets such as double-cone gaskets, weld-ring gaskets, ring-joint-gaskets or lens gaskets

- to examine custom structures which deviate from the standard