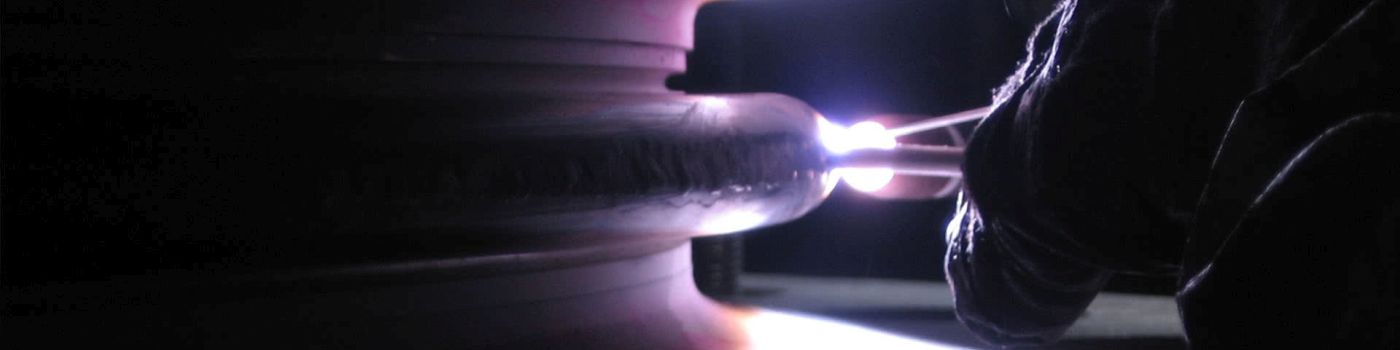

DESIGNING SEALED CONNECTIONS AND SPECIAL GASKETS

Experience and knowledge of seals and sealing materials

The designing, construction, calculation and specifications of gaskets and sealed connections require a great deal of experience and knowledge about how gaskets and sealing materials behave under various operating conditions. The mere application of well-known guidelines such as ASME, DIN EN 13445 or AD 2000 and purely examining the gasket or sealed connection using gasket parameters such as DIN EN 13555 say nothing about the leak tightness of a flange joint in the relevant installation or operating conditions.

We can offer you a complete service, starting with a preselection of suitable materials and suitable types of gaskets, to the design and specifications of the required components, right up to coordinating with the corresponding third party organisation (notified body) or ASME inspection agencies.

Design criterion seal

design parameter gasket

The gasket parameters determined using standardised test rigs, especially the results from leakage tests, frequently serve as a basis for selecting the gasket. However, an integral examination and design must be carried out to produce tight flange joints.

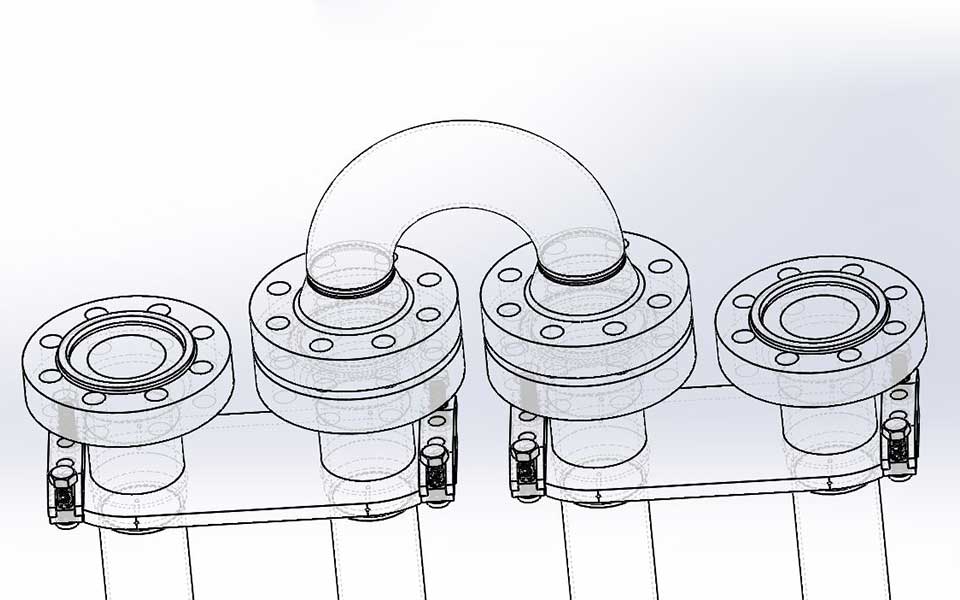

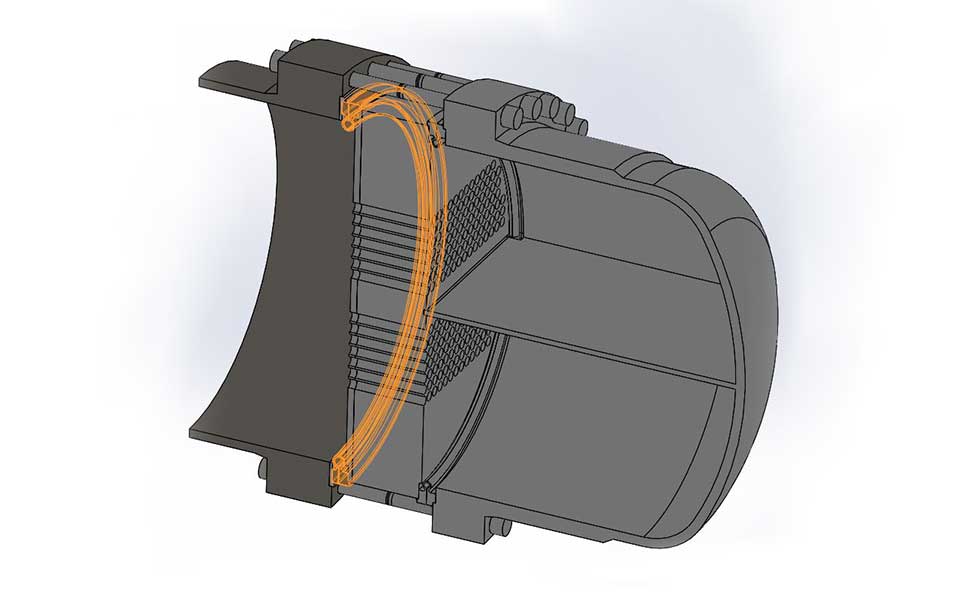

The construction and

design of sealed connections

- with gaskets at the main power connection

- with gaskets within metal to metal contact types

- flange joints on heat exchangers

- flange joints with clamped tubesheets

- with metal gaskets such as double-cone gaskets, weld-ring gaskets, ring-joint or lens gaskets

Calculations for

- sealed connections in accordance to DIN EN 1591-1

- sealed connections in accordance to DIN EN 13445 and DIN EN 13480

- sealed connections in accordance to KTA 3211.2 (metal to metal contact type)

- sealed connections in accordance according to ASME Section 8 Division I and Division II

- sealed connections in accordance to the KEMPCHEN calculation rules for rectangular flange joints

- sealed connections in accordance to the KEMPCHEN calculation rules for weld ring flange joints

- tightening torques for assembling the flange joints

- leak tightness certificates considering IPPC, TA Luft / VDI 2290