SPECIAL GASKETS

» DOUBLE SEALING SYSTEM

» SPLATTER-SHIELD STRIPS

» BAFFLE SEALS T4

» KEMSTHERM

» KEMSHAPE

DOUBLE SEALING SYSTEM

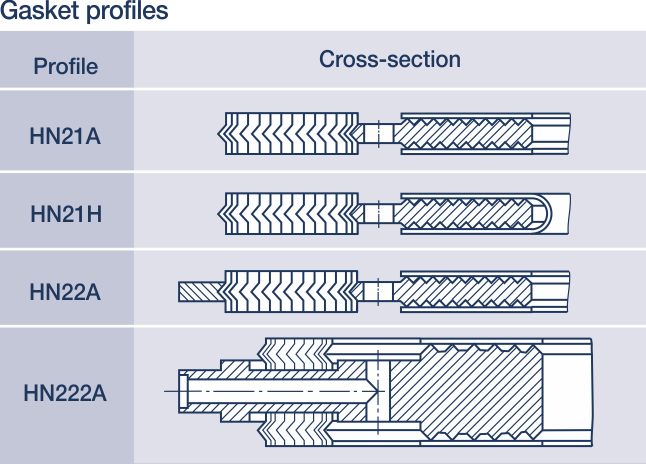

KHS / KNS with intermediate exhausting

Old and new plants constantly place greater demands on safety and reliability. This applies at certain sizes to bolted flange connections on apparatuses, valves and pipelines. For many years, sealing systems with intermediate exhausting or certain areas of the chemical industry. The simplest example of this consists of two O-rings concentrically arranged in grooves.

Similar designs are problem-free, as long as the components to be sealed are inherently stable and retain their position relative to each other. The bolt load applied, the internal pressure, the temperature or even external forces and moments all cause the flanges to take on a certain angle to each other, and so large deformations in the area of the seal should be anticipated.

Design and operation

The use of some gaskets leads to noticeable difficulties if the gasket is not able to securely seal the flanges as they slant against each other. Therefore the problem is even more difficult when two concentrically aligned gaskets are used.

If both gaskets are aligned as a main load seal or else if both are in off load contact, in each case significantly greater sealing recovery proportionate to the lever arms is required from a gasket than from other gaskets.

In many cases it has proven preferable not to have the components so inherently stable, so that leaks can be avoided with the pressure applied or with large applications of force.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

![]() Product documentation DOUBLE SEALING SYSTEM (pdf)

Product documentation DOUBLE SEALING SYSTEM (pdf)

SPLATTER-SHIELD STRIPS

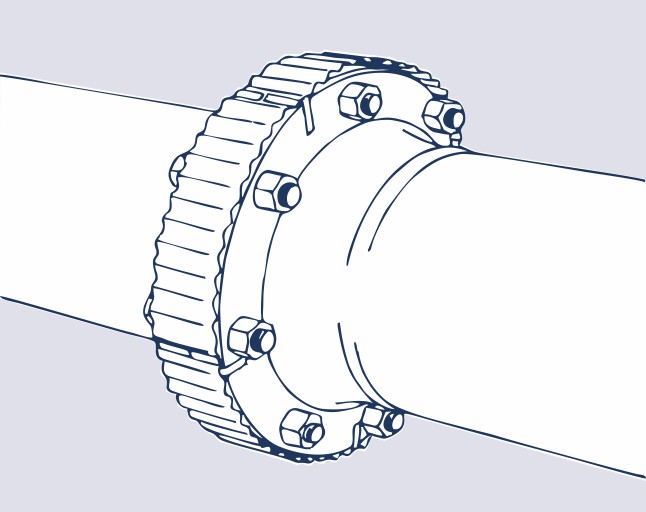

Dangerous, hot or pressurised media are transported through pipelines in many branches of industry. Wherever these pipelines are connected to each other with bolted flanges, there is a danger that a leakage of the dangerous medium will occur, leading to an accident.

This can involve acids or alkalis, high-pressure steam or boiling water, high-pressure hydraulic oil or heat-carrying oil, compressed air or water, to name the most important sources of danger.

Design and operation

Splatter-shield strips in Profile BWQ are made from 0.2 mm thick stainless steel strip of material 1.4541. They are corrugated at right angles to the length. When used with a flange connection, the corrugation along the strip creates many small openings to the outside.

This means that the dangerous medium cannot stream out directly onto a person standing in front of the flange connection. Instead, the stream of acid, alkali or water will hit the interior of the splatter-shield strip and then flow at low pressure through the opening.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

BAFFLE SEALS T4

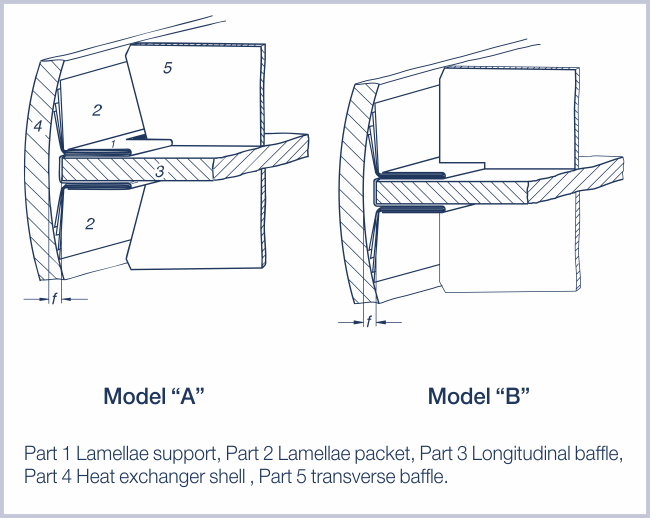

Seal for sealing longitudinal baffles in high-performance heat exchangers.

Baffle seal profile T4 is a full metal seal. It is generally made from 1.4571 steel for the lamellae supports and for the lamellas themselves. On request for larger these seals can also be produced from other spring-elastic steels or non-ferrous metals.

We are able to produce precisely adapted separating plate gaskets for every heat exchanger. Particularly suitable for heat exchangers with large or small gaps, due to construction filters, refurbishment or warping.

This seal plays an important role in effectively sealing the gap between the longitudinal baffle and the heat ex-changer shell in high-performance heat exchangers. In par-ticular, when there are small differences in temperature, even low short-circuit currents cause a significant power loss. This can largely be avoided by using the baffle seal T4. The T4 seal is easily assembled directly onto the longitudinal baffle.

No bolts are required to affix it. This means that there is no need to drill holes or to do any of the usual bolting work during assembly.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

KEMTHERM

Developed for your safety!

KemTherm is a static seal for standard and non-standard flange connections, with an integrated thermal element for very accurate measurement of the flow medium temperature.

The measurement signal can be integrated and processed in all process control systems and can be used to control and regulate processes.

Function

KemTherm is available as a grooved gasket type B15T. A thermal element is integrated into the carrier core, which makes it possible to measure the temperature over the entire 360° circumference. The temperatures are recorded and made available as averaged values.

APPLICATION

If the temperature is to be measured in a pipeline system, this can currently be done with the aid of a built-in sensor or a contact sensor. Both variants have specifi c disadvantages. An immersion sensor is extremely complex to install and disrupts the pipe flow.

A contact sensor is very strongly dependent on the ambient conditions and delivers very imprecise measured values. KemTherm has none of these disadvantages.

It is very easy to install at any point of the flange connection, and provides an accurate temperature reading and can be used up to an operating pressure of 160 bar and a maximum operating temperature of 400°C. The KemTherm gasket can be installed on flange connections with sealing surface shapes A and B according to DIN EN 1092, and shape RF according to DIN EN 1759.

The dimensions of the gasket core do not comply with current standards, but are rather optimised specifically for improved temperature absorption. Overall seal height before installation and centering diameter corresponds to the standard seals of the standards DIN EN 1514 and DIN EN 10260.

ADVANTAGES

- The pipe flow is not affected

- Simple subsequent installation by changing the gasket

- No “trouble spots” (potential leaks) appear along the pipe section

- Installation is possible at any flange connection

- KemTherm is weatherproof

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

KEMSHAPE

Representation of sealing surface damage

Function

The impression material is prepared in equal parts from a Base and a Catalyst. When the two components

are mixed, a modelling compound similar to plasticine is produced, which is then applied to the

damaged areas of the sealing surface. When applying the impression material, make sure that the

entire area of the sealing surface is covered from the outside diameter of the sealing strip to the inside

diameter of the flange.

When the impression material is pressed on, it produces a detailed 3-dimensional image of the

surface damage.

After application and pressing, the impression material must harden for approx. 3 to 6 minutes and can then

be carefully removed. After detachment, the result can be directly assessed, macroscopically. All details are

clearly visible in the impression.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.