PTFE-ENVELOPED GASKETS

In flange connections where there are high levels of chemical attack, PTFE flat gaskets are used. Due to the cold flow affinity of unfilled PTFE, use is mainly made of PTFE composites and PTFE-enveloped gaskets which have increased resistance to stress relaxation.

Because of their high chemical resistance and outstanding sealing properties, PTFE-enveloped gaskets have proven excellent when used at fluctuating pressures and temperatures ranging from -195 °C to +250 °C. Glass tubes, metal-enveloped glass tubes and glass equipment from laboratory or pilot installations can be connected up as easily as enamelled, coated or lined pipes and equipment in large plants.

PTFE-enveloped gaskets are particularly useful with aggressive chemicals in the chemical industry, due to their high resistant strength. PTFE is also physiologically harmless, and so can be used in the food and pharmaceutical sectors.

Apart from their high resistance to chemicals, PTFE is also extremely anti-adhesive. This non-stick effect means that no material will adhere to the surface of the PTFE.

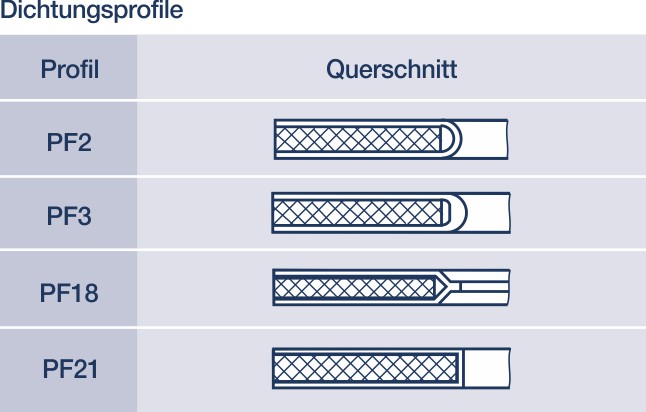

PTFE-enveloped gaskets consist of a stable gasket insert and a PTFE envelope. Only high-quality, non-porous PTFE is used for the envelope, so as to protect the insert against chemical attack. The PTFE envelopes are open onto the outer or inner diameter, or encase the entire insert, depending on what is required. The envelope is 0.5 mm thick and therefore very stable. Lathed envelopes can be produced with an internal diameter 2 to 4 mm thicker to provide greater diffusion sealing.

For dimensions see the section 3 ”Flat gaskets made from Graphite, Fibre, PTFE, Elastomer“.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.